Tata Motors Files Patent for Game-Changing Gearbox: A Deep Dive into the Patent Summary and Innovation

As the automotive industry shifts towards sustainability and efficiency, transmission technology is at the heart of this transformation. Tata Motors has recently filed a patent for an innovative gearbox that promises to improve performance while enhancing fuel efficiency. This article delves deeper into the patent, providing technical insights, industry impact, and potential applications in light of evolving transmission technologies.

Patent Claims:

1. A lubrication system for a gearbox assembly with improved flow dynamics.

2. Enhanced gearbox durability through optimized lubricant distribution.

Problem Statement Summary

The intricate dance of gears within a gearbox requires a precise and consistent supply of lubricant to ensure optimal operation. However, conventional lubrication systems often fall short, leading to premature component failure and compromised vehicle efficiency. Recognizing this critical challenge, Tata Motors, a global automotive leader, has taken a groundbreaking step by filing a patent for an optimized lubrication system designed to revolutionize gearbox performance.

Conventional gearbox lubrication systems often suffer from:

– Inadequate lubricant distribution

– Insufficient cooling

– Increased wear and tear

Emerging Gearbox Technologies: What Sets Tata’s Innovation Apart?

In an industry driven by constant improvement, gearboxes are undergoing significant transformations. Tata Motors’ new gearbox design aims to tackle issues such as energy loss and performance degradation in traditional transmissions. This new system incorporates advanced materials and electronic controls to optimize torque transfer and reduce mechanical friction. Unlike conventional systems, it is designed to deliver smoother gear shifts, which directly translates to a better driving experience and improved fuel efficiency.

Technical Innovation: What the Patent Tells Us

Tata’s patent highlights several key innovations:

- Advanced Materials: The use of lightweight, durable materials enhances the gearbox’s longevity and performance. This reduces wear and tear, which is a significant factor in the efficiency of conventional gearboxes.

- Electronic Control Integration: Tata’s system leverages advanced sensors and AI to monitor gear performance in real time. The control unit adjusts gear shifts dynamically, depending on driving conditions, which improves overall power management.

- Improved Torque Distribution: The patent outlines a novel mechanism for managing torque between gears, resulting in better acceleration and more controlled power distribution, particularly in electric and hybrid vehicles.

Expert Opinions on Gearbox Trends

Industry experts have long emphasized the need for smarter, more efficient transmission systems, especially with the rise of electric and hybrid vehicles. According to a study from Power Transmission Engineering, gearboxes are evolving to manage the high torque of electric motors while maintaining efficiency. Tata’s gearbox technology appears to be a step in this direction, integrating key trends like material science advancements and smart controls Power Transmission

The Gearbox Lubrication Conundrum: Balancing Efficiency and Durability

Effective lubrication is paramount to the health and longevity of a gearbox. It serves as a protective barrier between moving components, reducing friction, preventing wear, and dissipating heat. However, achieving optimal lubrication can be a complex task due to various factors. Conventional systems often struggle with inadequate lubricant distribution, insufficient cooling, and increased wear and tear, resulting in compromised gearbox performance and reduced vehicle efficiency.

Tata Motors’ Innovative Solution

To address these challenges, Tata Motors has developed an innovative lubrication system that incorporates several key features:

- Improved Flow Dynamics: The system is designed to enhance lubricant circulation and distribution within the gearbox. This ensures that all critical components receive an adequate supply of lubricant, minimizing the risk of premature wear and failure.

- Dual-Stage Filtration: Contaminants such as dirt, metal particles, and other debris can significantly degrade the performance of a lubricant. Tata Motors’ system employs a dual-stage filtration process to effectively remove impurities, ensuring that the lubricant remains clean and pure throughout its service life.

- Temperature-Controlled Lubricant Supply: The viscosity of a lubricant can be affected by temperature fluctuations. To maintain optimal performance, Tata Motors’ system includes a temperature control unit that regulates the lubricant’s viscosity, ensuring that it provides the necessary protection and lubrication under varying operating conditions.

- Condition-Based Monitoring: To proactively identify potential issues and prevent catastrophic failures, the system incorporates condition-based monitoring capabilities. Sensors continuously monitor the lubrication system’s performance, allowing for early detection of anomalies and timely maintenance interventions.

System Architecture: The proposed lubrication system consists of several key components:

- Lubricant Reservoir: This stores the lubricant that is circulated throughout the system.

- Dual-Stage Filter: A high-efficiency filter that removes contaminants from the lubricant.

- Temperature Control Unit: A device that regulates the lubricant’s temperature to maintain optimal viscosity.

- Condition Monitoring Sensor: Sensors that monitor the system’s performance and detect potential issues.

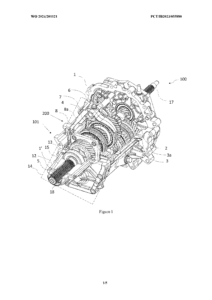

Alt text for visually impaired person: A detailed cutaway view of a mechanical transmission unit, showcasing multiple gears, shafts, and a protective casing. Labels identify specific parts, including the gears, input shaft, and housing, highlighting the internal mechanisms responsible for power transmission. - Gearbox Assembly Interface: The connection point between the lubrication system and the gearbox.

Comparative Analysis: Where Tata’s Gearbox Stands in the Market

When compared to other gearbox innovations, such as those highlighted by Verified Market Reports, Tata’s new system seems to offer a more comprehensive solution, addressing not just one, but several major pain points in the industry Power Transmission. While other systems focus on torque or fuel efficiency, Tata’s system takes a holistic approach by incorporating both advanced material technology and smart electronic controls.

- Competitor Systems: Many recent gearbox designs aim to reduce energy consumption, but few go as far as integrating AI-driven sensors for real-time performance adjustments. This positions Tata’s system as a more forward-thinking solution, especially in markets shifting towards electric vehicles (EVs).

- Potential Industry Impact: This patent could have a significant influence on the future of electric and hybrid vehicles, where managing torque and reducing mechanical friction are key to maximizing battery life and performance.

Future Scope: Transforming Vehicle Transmission Technology

Tata Motors’ innovative lubrication system has the potential to significantly transform vehicle transmission technology. By optimizing lubricant flow, filtration, and temperature control, this technology offers several key benefits:

- Increased Fuel Efficiency: Reduced friction and improved lubricant distribution can lead to increased fuel efficiency, as less energy is wasted on overcoming resistance.

- Extended Gearbox Life: By minimizing wear and tear, the optimized lubrication system can extend the lifespan of the gearbox, reducing the need for costly repairs and replacements.

- Improved Vehicle Performance: Smoother gear shifting, reduced vibrations, and enhanced overall transmission efficiency can result in a more enjoyable and satisfying driving experience.

Applications in the Real World: From EVs to Commercial Vehicles

Tata Motors’ new gearbox technology is not limited to passenger cars. Given its emphasis on durability and energy efficiency, this system could be a game-changer for commercial and heavy-duty vehicles. In these applications, efficiency and reliability are critical, making this gearbox a versatile solution across the automotive spectrum.

- Electric Vehicles (EVs): For EVs, where power efficiency is paramount, this gearbox offers precise control over torque distribution, reducing unnecessary power consumption and extending the vehicle’s range.

- Commercial Vehicles: Heavy-duty vehicles stand to benefit from the system’s durability and adaptive torque management, ensuring performance under heavy loads while keeping fuel costs low.

Conclusion: Tata Motors’ Contribution to a More Efficient Future

Tata Motors’ gearbox patent represents a significant leap in transmission technology. By combining advanced materials with intelligent control systems, this innovation promises to enhance both performance and energy efficiency across various vehicle types. As the industry continues to move towards sustainable mobility solutions, such patents will play a pivotal role in shaping the future of automotive engineering.

This deep dive into Tata Motors’ innovative gearbox illustrates the company’s commitment to staying ahead of industry trends while addressing the evolving needs of consumers. As more details emerge, it will be interesting to see how this technology shapes the competitive landscape of the automotive sector.

Sources & Further Reading

- Power Transmission Engineering: Deep analysis of gearbox technology advancements

.

- Verified Market Reports: Emerging trends in gearbox technologies

.

https://itsallaboutpatents.com/?post_type=web-story&p=136

Following Credit is mentioned in Patent as

Applicants

- TATA MOTORS LIMITED

Inventors

- R, Samson

- GURAV, Onkar

- SHAH, Sourabh

- PILLAI, Vipin

- BANGAR, Sandeep

- DHAKRE, Sameer

- MEHRA, Abhinav

Publication Date 03.10.2024